Welcome to Our Company

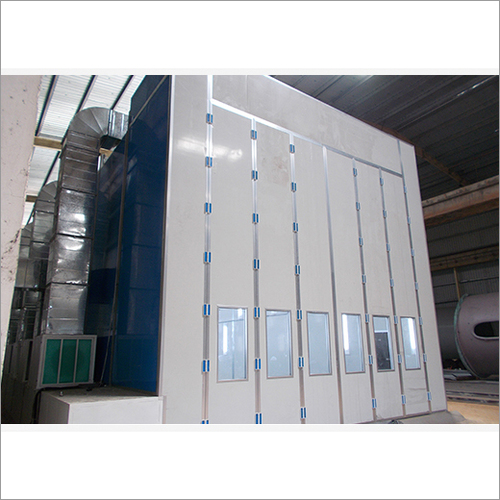

Powder coating Booth With Oven

700000.0 INR/Kilograms

Product Details:

- Type Powder Coating Booth with Oven

- Surface Powder Coated

- Technology Electrostatic Powder Coating

- Attributes Easy maintenance, Energy efficient, High performance

- Power Source Electric

- Power Consumption 3 - 5 kW (booth), 12 - 18 kW (oven)

- Voltage 220-240V (single phase) or 415V (three phase)

- Click to View more

X

Powder coating Booth With Oven Price And Quantity

- 1 Kilograms

- 700000.0 INR/Kilograms

- 500000.00 - 1500000.00 INR/Kilograms

Powder coating Booth With Oven Product Specifications

- 3 - 5 kW (booth), 12 - 18 kW (oven)

- Yes

- Electric

- Yes, with safety interlocks

- Easy maintenance, Energy efficient, High performance

- Mild Steel (MS)

- Powder Coated

- 220-240V (single phase) or 415V (three phase)

- Single

- Powder Coating Booth with Oven

- Electrostatic Powder Coating

Powder coating Booth With Oven Trade Information

- 4 Kilograms Per Month

- 1

- Middle East, Central America, Asia, South America, Eastern Europe, Western Europe, Africa, North America, Australia

- All India

Product Description

Owing to our rich industrial experience, we have been a prestigious manufacturer of Powder coating Booth With Oven in the market. This provides an extremely efficient means for removing paint particles from the exhausted air by using water as a filtration media.Powder coating Booth With Ovenis utilized for high volume paint usage.

Customizable Chamber for Diverse Needs

Whether for automotive parts or industrial furniture, this powder coating booth features a customizable chamber size to meet your specific production requirements. The standard size offers ample working space, while modification options ensure suitability for varying component dimensions. This versatility helps streamline different coating processes in one efficient unit.

Advanced Safety and Control Systems

Equipped with digital temperature controllers, process timers, and safety interlocks, this booth provides reliable operation and peace of mind. Features like over-temperature protection and emergency stop switches add further safeguards. The integrated control system allows precise adjustment and monitoring, supporting high-quality finishing while minimizing risks.

FAQ's of Powder coating Booth With Oven:

Q: How does the integrated air flow system contribute to powder coating quality?

A: The booth's air flow system uses efficient filtration and a high-performance centrifugal blower to maintain a clean working environment. By constantly circulating and filtering air, it prevents contamination and helps achieve a uniform, smooth finish on coated surfaces.Q: What types of powder are compatible with this booth and oven?

A: This unit supports both thermosetting and thermoplastic powder types. The electrostatic powder coating technology ensures effective adhesion, catering to a wide range of substrates commonly used in automotive, furniture, and industrial manufacturing.Q: When should the oven's temperature controller and process timer be set?

A: The digital temperature controller and process timer should be configured prior to operation, based on the specific powder type and coating requirements. Accurate settings ensure consistent curing and optimal finish quality, while also enhancing energy efficiency.Q: Where can the powder coating booth with oven be installed?

A: The booth is designed for floor-mounted installation and can be set up in factories, workshops, or industrial sites across India. Its portable feature allows for repositioning within facilities when needed, enhancing operational flexibility.Q: What is the process for maintaining the multi-stage cartridge filter system?

A: Regularly inspect and clean the multi-stage cartridge filters to maintain airflow efficiency and exhaust performance. Replacement schedules vary by usage intensity, but easy-access design simplifies filter changes, keeping the booth running efficiently.Q: How does the protection system improve user safety during operation?

A: Safety interlocks, over-temperature protection, and an emergency stop switch are some features that enhance user safety. These mechanisms automatically cut off power or halt processes in hazardous conditions, helping prevent accidents and equipment damage.Q: What are the primary benefits of using this powder coating booth and oven?

A: Users benefit from high performance, energy efficiency, easy maintenance, and customizable operation. The smooth, powder-coated non-corrosive finish, digital controls, and robust safety systems make it an ideal solution for professional powder coating applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese